These commercial-size foam fractionators are extremely efficient at removing dissolved organics and pollutants. They utilize Airmaster aquafoil design that injects microbubbles into a pressurized water flow where it mixes in the water column. The dissolved organics and pollutants are attracted to the microbubbles and rise into a waste collection cup. These foam fractionators are compatible with ozone. Foam collection cups have large surface area for foaming and easy maintenance. Fresh and salt water compatible, applications include aquaculture recirculating systems, aquarium/ zoological exhibits, mammal exhibits, seafood-holding systems, ornamental ponds and shrimp systems.

Product Benefits: Foam fractionation offers several important benefits that improve water clarity and increase dissolved oxygen levels. This mode of filtration separates harmful dissolved organic waste from water before the biological filtering process takes place, reducing the load on the biological filter. By removing dissolved organic waste traditional large water changes are reduced lowering water and salt costs.

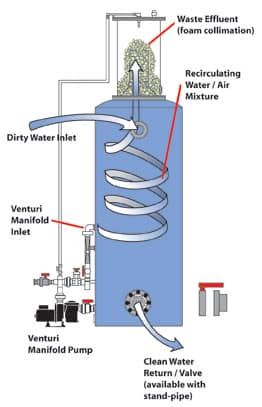

Foam fractionation is an efficient, cost-effective way to remove small particles and dissolved organic wastes from water while at the same time increasing dissolved oxygen levels. The Foam fractionator mixes air and water together through the Airmaster aquafoil. As the air bubbles travel upward through the water column, they collect dissolved, and small organic waste particles on their bubble walls. These bubbles create foam that accumulates at the top of the column, and develops up through the foam tube. As the foam accumulates it eventually falls out of the foam tube in to the foam collection cup, separating from the water inside the vessel. Several names have been given to this form of filtration such as protein skimming, protein stripping, or foam fractionation.

Construction Materials:

Important factors that effect the efficiency:

Recommended Applications

| Code | Size (Diameter x Height) | Design Flow | Maximum Flow | Inlet | Outlet |

|---|---|---|---|---|---|

| AAFF250 | 250 mm x 2200 mm | 3 m³ | 4 m³ | 1 ¼" | 1 ½" |

| AAFF300 | 300 mm x 2200 mm | 4 m³ | 6 m³ | 1 ½" | 2" |

| AAFF500 | 500 mm x 2200 mm | 11 m³ | 16 m³ | 1 ½" | 2 ½" |

| AAFF600 | 600 mm x 2500 mm | 19 m³ | 27 m³ | 2" | 3" |

| AAFF700 | 700 mm x 3000 mm | 31 m³ | 45 m³ | 2" | 3" |

| AAFF900 | 900 mm x 3000 mm | 45 m³ | 60 m³ | 3" | 110 mm |

| AAFF1000 | 1000 mm x 3000 mm | 63 m³ | 92 m³ | 110 mm | 160 mm |

| AAFF1200 | 1200 mm x 3000 mm | 108 m³ | 150 m³ | 125 mm | 225 mm |