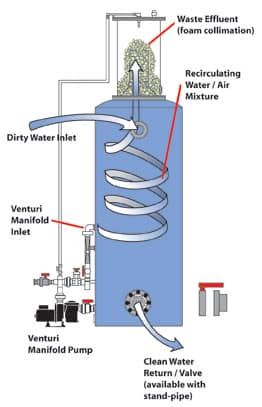

Protein skimming or foam fractionation is the process by which dissolved and particulate organic carbons are removed from a liquid, in this case the fish culture water, by adsorbing them onto the surface of fine bubbles rising in a closed contact column. The bubbles form stable foam at the top of the water column and the accumulated organic wastes are discharged from the column along with the foam produced. The removed substances are called "surfactants" because they are surface active or "charged"

Improved technology has made it possible to skim off harmful protein compounds. Airmaster protein skimmers are specially developed for these applications making them the ideal protein skimmer for your waste water cleaning requirements. These skimmers remove proteins before they decompose to toxic compounds, they reduce turbidity and typically the water will be deodorised as well.

Benefits of Protein Skimming include:

Important factors that effect the efficiency:

Bubble size is the most important of these and within the design of the Airmaster protein skimmer an efficient method of microbubble production is the most important part in ensuring maximum surface area for the adsorption of the organic compounds. Smaller bubbles also rise more slowly, allowing more contact time with the process water.

Higher powered, higher flow rated pumps of 4000 litres per hour or more are ideal for use with the Airmaster Aquafoil type protein skimmers. This unique process produces millions of microbubbles whilst minimising back pressure on the pump, so that flow rates are hardly affected. This helps to maintain the efficiency of the AAFF and AAPS range of protein skimmers.

Protein skimming is also enhanced by including ozone into the air mixture, which further oxidises and breaks down complex organic compounds as well as providing a degree of disinfection, depending on the quantity used.

Sizing a Protein Skimmer Successful removal of dissolved organic compounds is all about contact time - the amount of time the bubbles have in contact with the water flowing through the skimmer.

So deciding on which skimmer to have may be dictated by either the size of pump available, the volume of water to treat or the rate at which it is treated.

Skimmers are available in different sizes, but they all do the same job, the difference is in the capacity of the the skimmer body- the volume it holds, this is the key to the rate at which water can be treated.

A 'contact time' of 90 seconds is usually regarded as the optimum time for bubble/water flow contact in the vessel.

We indicate flow rates and contact times in the product specifications to allow you to decide which protein skimmer is most appropriate for your requirements.

Installing a Protein Skimmer. AAPS (airmaster aquafoil) type protein skimmers are similar to install.

Both are pump fed and gravity return, they do not pressurise internally.

Water flow from your pump is connected to the inlet valve, with the AAPS it will pass through the airmaster venturi and then into the skimmer.

The outlet return can overflow directly to another part of the filtration system not requiring a pressurised flow, to a holding tank or pond, so long as all of these are below the initial outlet height.

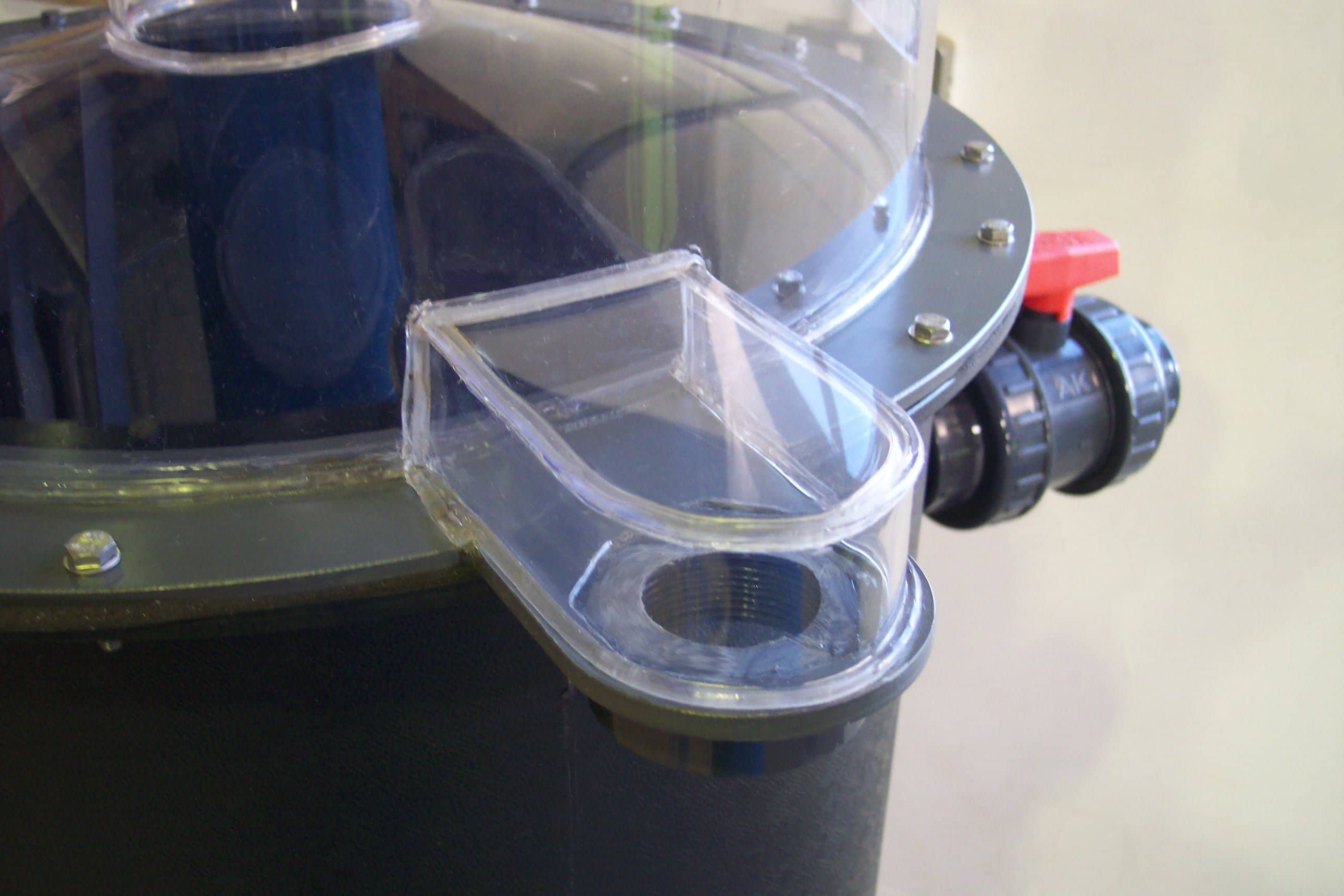

Waste from the foam outlet can be disposed of or reused as a high quality liquid fertilizer. Operation of a Protein Skimmer. Freshwater foams can be very weak and collapse readily, so setting the water level in a protein skimmer is a critical part of successfully operating one. The water level can easily be seen in the transparent cone and foam tube in the top of the skimmer. By adjusting the inlet and outlet valves the water level can be raised or lowered to a point where just the foam will discharge from the foam tube into the foam collecting chamber on top of the skimmer.Once set this level will remain constant, provided the delivery from the pump remains constant also. If the pump is used simultaneously for other applications these probably will have an effect on the operation of the skimmer.